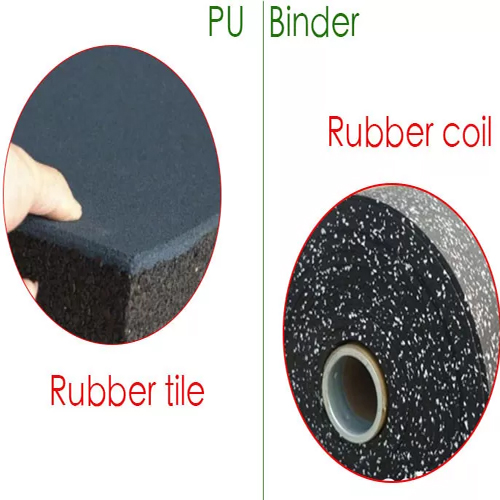

PU Binder

PU Binder

Since its invention, polyurethane has been one of the most important compounds, with numerous applications. A leading participant in coating and printing applications, polyurethane is known for its flexibility, strong chemical structure, and user-friendly qualities.our one-component, moisture-curing, unpigmented PU binders are DESMOTOP-RR 2009 and DESMOTOP-RR 2008. Timber, polystyrene foam, plastic, urethane foam, reclaimed rubber, gravel, cloth, metal surfaces, and many more substrates can be bonded with these. Substrate, ambient temperature, and relative humidity determine the PU binder cure rate. Using a hot press on PU binder can drastically shorten the curing period.

| Property | Unit | DESMOTOP-RR 2009 | DESMOTOP-RR 2008 |

| Appearance | Yellowish liquid | Clear liquid | |

| NCO content | % | 10 ± 0.3 | 11 ± 0.5 |

| Solid content | % | > 99 | 100 |

| Density at 25°C | % | 10 ± 0.3 | 11 ± 0.5 |

| NCO content | g/cm3 | 1.08 ± 0.05 | 1.09 ± 0.03 |

| Viscosity at 25°C | cps | 2200 ± 500 | 2400 ± 500 |

| Flash point | oC | > 200 | > 200 |

| Tack free time at 25°C/50% rel. hum. | hr | 4-6 | 4-6 |

- Features

- Advantages

- Usages

- Packaging

- Polyurethane Binder

- Simple to transport and put away

- Quite simple to handle

- Strongest possible connection

- Immaculate transparency